Magnetek offers packaged automated No-Fly Zone Systems

Advanced automation solutions for maximum performance and safety

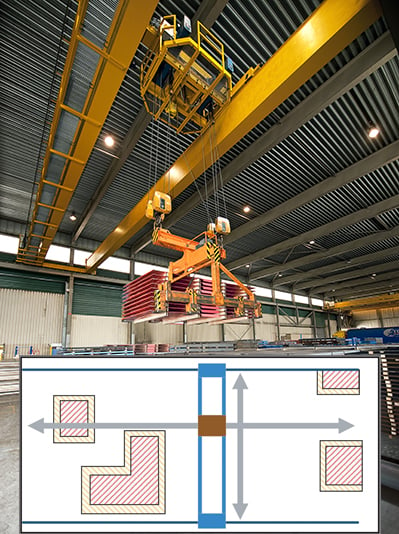

Columbus McKinnon Corporation, a designer and manufacturer of motion control products, technologies, and services for material handling, now offers Magnetek Fixed Location and Configurable No-Fly Zone Systems as options for personnel and facility safety. No-fly zones refer to protected areas where normal crane operation is limited or entirely restricted. Depending on application needs, No-Fly Zone Systems may incorporate a variety of motion control products, including variable frequency drives, radio remote controls, limit switches, and sensors that designate locations where a crane is programmed to stop.

“As a component of our automated systems family, no-fly zones are able to directly improve the safety of equipment operators and work environments,” said Jim Kluck, global product manager for controls and automation. “Two-step safety areas limit the risk of collisions by utilizing an initial no-fly zone where crane movement is prohibited, in addition to an extended warning zone where a slow speed limit is enforced.”

These versatile systems—ranging from simple to complex configurations—can be added to existing crane controls or introduced as new installations for a variety of industries including automotive, steel, manufacturing, and pulp and paper. Fixed location No-Fly Zone Systems utilize limit switches installed on bridge and trolley motions that interface with a controller for system functionality. Fixed location configurations are optimized for two-sided, three-sided, or four-sided applications.

Fully configurable No-Fly Zone Systems utilize laser positioning sensors installed on bridge and trolley motions that interface with controllers for functional customization. These systems incorporate a simplified menu-driven operator interface accessed over a 2.4 or 5 GHz wireless connection via the use of a Personal Electronic Device (PED) such as a laptop, smartphone, or tablet. This operator interface provides flexibility to configure no-fly zones and enable or disable as changing process, plant, and crane conditions require. Fixed location and configurable No-Fly Zone Systems include a panel-mounted, key operated two-position enable or disable switch. This allows users to bypass the no-fly zone programming and permits manual crane operation if required.