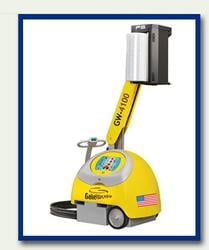

ITW Muller offers greater efficiency, safety and mobility with GW-4100

ITW Muller introduces its highly mobile GW-4100 robotic pallet wrapper. This latest solution offers increased product protection and wrapping consistency, improved employee safety, less waste and significant time and cost-savings over hand-wrapping. The GW- 4100 robotic pallet wrapper boasts speeds of 37 loads/hr and comes standard with a telescoping mast that allows for easy mobility, accommodating loads up to 6’11”high (93”). Its built-in film cutter cuts film at completion of wrap cycles and minimizes risk of operator injury. In addition, the GW-4100 has an independent top and bottom wrap pattern selection from 1-20 wraps. Optimized for use with ITW Muller Oriented Film, the film tension can be adjusted electronically from the control panel. With a height adjustable mast, the GW-4100 can easily move around a warehouse and is easy to install, often up and running within minutes of installation. The technology is efficient and flexible- it can perform 300 loads per charge, comes pre-set with 99 wrap cycles and can be programed with an unlimited number of options. The machine also offers several safety features including an emergency stop button, safety contact edge and low voltage which reduces shock hazard. “This GW-4100 is one of our most versatile and efficient technologies available offering significant savings, high performance and greater safety features,” says Michael Klear, Market Development Manager, ITW Muller.