Building mufflers not an exhausting process

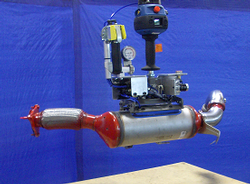

A Cynergy Ergonomics vacuum lifter recently installed in a major automotive manufacturer lifts and repositions exhaust assemblies in and out of work cells, holding the assemblies firmly even as their weight increases throughout the manufacturing process. The purpose-designed lifter allows an operator to lift a part from one cell to the next in 4-5 seconds, while also allowing a change in the parts orientation if necessary. The vacuum cup tooling allows for use in applications with elevated temperatures while the “part present” technology prevents the releasing of the part until it is properly seated in the next cell. Without installing the Cynergy Ergonomics vacuum lifter this process would be completed manually, but now operators can move the exhaust assemblies with virtually zero effort. Because of this users have eliminated their recordable injuries and the inherent problems that surround an elevated risk process.

Cynergy Ergonomics engineers studied the task at hand, along with the plant environment and utilities available prior to recommending a solution. The resulting vacuum lifter uses Vi-Cas VC-90 oval vacuum cups to hold the assembly during the lifting and positioning process, and is powered by compressed air which was readily available nearby.