CarryMatic® No-Touch Materials Handling, an Autonomous Solution from Jtec Industries

Jtec Industries, Inc. introduced the new, hands-free CarryMatic® last April at Modex 2018 as a response to the need for autonomous solutions in the material handling industry. Since then it has gained traction with the materials movement world as a one-of-a-kind solution to making materials flow efficiently and safely.

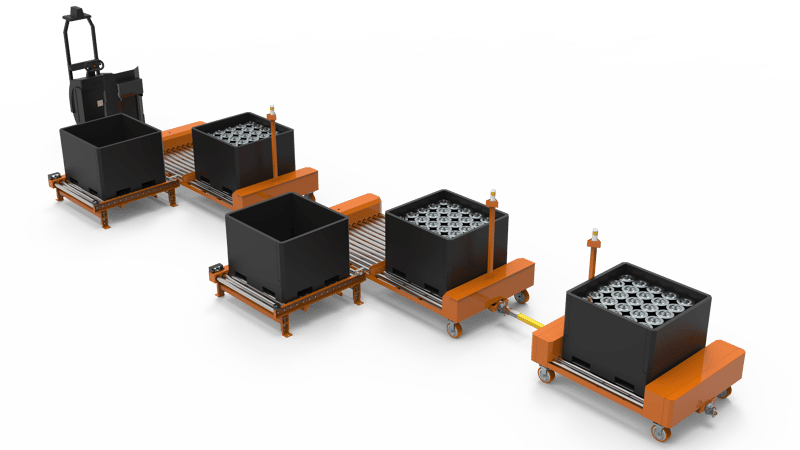

This delivery system utilizes a train of Smart Carts towed with an AGV (Automated Guided Vehicle) or an existing tugger cart, all managed by Jtec’s proprietary supervisory software. Once CarryMatic’s Smart Carts reach their Smart Line-Stations, loads are moved automatically by powered rollers, meaning employees never physically handle materials as they are loaded and unloaded from the carts.

When paired with an AGV in Auto Mode, CarryMatic® becomes an autonomous system without the need of an operator, reducing manpower needs and associated safety concerns while increasing productivity and accuracy with routine milk run deliveries. Routing options available include pre-programmed routes or a dispatch method, both creating a consistent materials movement that is guaranteed to improve delivery times. A network of sensors supplies real-time information on station statuses and locations while assisting with cart and station alignment during transfers.

CarryMatic® integrates easily in Manual Mode with the existing manned tuggers already used in your facility. A VIM (vehicle interface module) incorporated on existing tuggers communicates to CarryMatic’s supervisory software to direct deliveries, loading and unloading. Even with this option, an operator never touches any load.