Analysis of the Top Nine misunderstandings about forklift lithium-ion batteries

1/6/7F-1 Building1 Zhongkai Innovative Base

Huifeng 6th Road ZhongKai Hi-tech Zone

HuiZhou City, Guangdong, INTL

http://www.lithiumforkliftbattery.com

Interest in and use of lithium-ion batteries in industrial trucks is growing. There are many advantages to this revolutionary technology, most notably its fast charging and ability to charge “on the go” rather than “charge to full” all at once.

However, there remains widespread confusion and misunderstanding about battery technology and its suitability for material handling applications.

Visit our Forklift Lithium Battery website or read on for what BSL Battery – Industrial technical experts have to say about some misconceptions.

1. We do a lot of heavy lifting that electric machines can’t handle

With modern battery-operated equipment, lifting capacity is not an issue. If the capacity plate rating is the same as the equivalent internal combustion engine (ICE) model, the ability to lift heavier loads is also the same. For example, Hyster®’s updated J2.5-3.0XNL trucks are designed to match hydrostatic IC trucks. Also, remember that while lifting uses a lot of energy, electric forklifts are more energy efficient than IC forklifts, so the only real potential drawback is the machine’s ability to store and use that energy. This means the end user must consider whether there are sufficient opportunities to recharge the battery throughout the day.

This video provides an in-depth look at how lithium-ion technology works and how Hyster® can replace multiple lead-acid batteries depending on truck power requirements while increasing productivity!

2. You can get all the benefits by replacing your lead-acid batteries with lithium-ion batteries

Of course, aftermarket lithium-ion batteries are a huge improvement over lead-acid batteries, but to enjoy the real benefits, you should consider a forklift factory-approved OEM lithium-ion battery manufacturer, which has inherent advantages.

For example, the integrated battery has CANbus connectivity, which means the truck’s factory BDI still works accurately. The OEM technician can connect to the battery and diagnose any issues through the truck software, eliminating the need to call a 3rd party provider. In addition, BSL Battery is a major lithium battery supplier in China. It serves Toyota Material Handling, Combilift Forklift, Clark Forklift, Xilin Forklift and Raniero Forklift.

When considering a swap solution (lead-acid batteries replacing equivalent lithium-ion batteries), users must determine whether their application allows sufficient time to charge the batteries. They also need to consider additional energy infrastructure costs, such as cables and sockets capable of handling higher power consumption. In addition, they need to install new power points closer to work areas or break rooms to avoid unnecessary trips to existing lead-acid charging room distances.

3. Lithium-ion batteries are very expensive

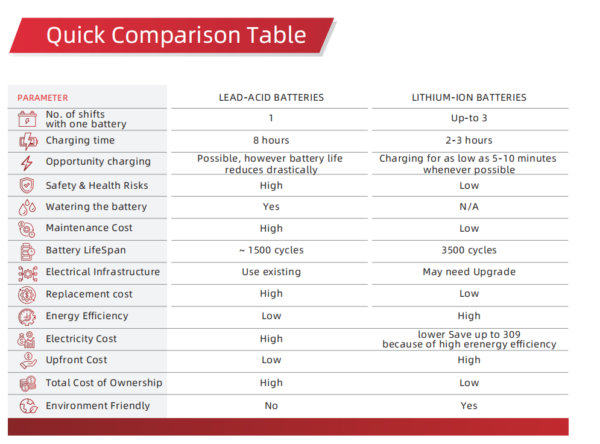

It’s imperative to think about long-term costs. Although lithium-ion batteries have a higher initial purchase price than lead-acid batteries, their cost per cycle is lower due to their longer lifespan, making them the most cost-effective solution in the long run.

BSLBATT’s lithium-ion batteries, in particular, have extremely low internal resistance and the most efficient technology, which means less grid energy is wasted and saves 30% (charging and CO2 emissions) compared to lead-acid batteries.

BSLBATT’s lithium-ion batteries, in particular, have extremely low internal resistance and the most efficient technology, which means less grid energy is wasted and saves 30% (charging and CO2 emissions) compared to lead-acid batteries.

Therefore, in the long run, with the decline of lithium carbonate, now comparing the prices of lithium-ion batteries and lead-acid batteries, purchasing a lithium battery with the same capacity only costs 1.5 times that of a lead-acid battery. Lithium batteries are cheaper in the long run.

4. We need to replace our entire lead-acid fleet with lithium-ion machines

Of course, it often makes sense to replace the entire fleet so that operators don’t have to switch between different charging regimes and operating procedures. It also makes sense for the aging fleet, which has decided to retire all existing machines and “start over.”

Replacement is also recommended when a business has an incentive to replace. This could be a commitment to reduce overall CO2 emissions or a desire to eliminate hazardous battery replacement or reduce ongoing maintenance requirements.

However, if the utilization of certain trucks is not sufficient to warrant lithium-ion batteries, a mixed fleet is possible and we have helped many customers with phased rollouts. If you operate a mixed fleet, you need to know that lead-acid and lithium-ion batteries often require different chargers, so charging areas may need to be marked and instructions provided to staff.

5. Our power supply must be upgraded

Yes, lithium-ion battery chargers have higher output, which means they require higher input current than lead-acid chargers. However, BSL Battery – Industrial offers a variety of battery/charger combinations based on utilization, application intensity, and available charging window. At the same time, to reduce customers’ charger investment, we have communicated with the world-renowned SPE, Fronius, and Delta-Q, which means that customers do not need to purchase additional chargers when switching to BSLBATT lithium batteries using chargers from these three brands. Charger!

6. Our drivers must be retrained and change their work habits

Agreed, retraining is required as standard AS2359:2 practice states that each user should have a safe work systems policy in place, including supervisory practices, on-the-job training, and ongoing regularly updated training. Therefore, users must maintain records of ongoing training.

The good news is that lithium-ion batteries are easy to use

- The battery management system communicates with the charger to prevent overcharging.

- It manages power delivery to prevent excessive discharge.

- It does not require charging or watering to work properly.

- The operator must simply know how to plug it into the charger when not used.

Our clients found that their work habits needed to change, but for the better. Battery maintenance tasks are virtually eliminated, as are hazardous battery replacement and battery damage due to battery misuse. Unlike lead-acid batteries, lithium-ion batteries thrive on opportunistic charging, meaning operators can charge the forklift during breaks. The charging process will be faster and easier since there is no longer a need to open the hood to connect the charger to the truck.

7. Lithium-ion batteries are not as stable as lead-acid batteries and pose safety threats

This is a common myth, but lithium-ion batteries are safer than traditional lead-acid batteries. Although the energy density is higher than that of lead-acid batteries, BSLBATT lithium-ion batteries have multi-level safety systems such as cells, modules, and casings, as well as a battery management system (BMS) with comprehensive protection functions. BMS protects against overload, overcharge, deep discharge, overcurrent, and short circuits. It also has world-class UL2580, IEC62619, CE, and UN38.3 certification testing!

8. Lithium-ion batteries last shorter than lead-acid batteries

Lithium-ion batteries have a longer cycle life, allowing them to be used effectively in applications where recharge opportunities are abundant. Because lithium-ion electrochemistry has higher energy density and voltage stability, as well as smaller internal resistance, it can bring higher power output, increased efficiency, and faster charging capabilities.

Lithium-ion batteries are expected to last about 4,000 complete cycles – compared to 1,500 for lead-acid batteries.

9. Lithium-ion batteries are not suitable for harsh environments

This isn’t true. Through extensive testing, we have found that lithium-ion batteries perform better than lead-acid batteries in rough surface environments, high-usage environments, low temperatures, and most other environments where lead-acid batteries have difficulty or simply fail to perform.

Depending on the application and use, lithium-ion batteries are available. Since the permissible operating and charging temperatures depend on each specific lithium-ion battery pack, BSLBATT provides data sheets and user manuals specifying the exact operating conditions for each truck.

As a concept of the maximum allowable working environment, BSLBATT forklift lithium-ion battery pack generally works like this:

| P+ Series | |

| Moisture/humidity | Protection class rating IP6K9K The battery can be used both outside and in buildings. |

| Operating temperature | -35°C to 60°C |

| Charging temperature | -20°C to 45°C (at temperatures below 0°C charging times will increase) |

| Storage temperature | -35°C to 80°C A storage temperature of -10°C to 50°C is recommended to avoid reducing the service life of the battery. |

| Suitable for use in a cold store | Yes |

| Areas where there is a risk of fire or explosion | No |

| Altitude | Use is possible up to a height of 2000m. |

(Note: “Hard environment” is a loose term that can be applied to many different applications. BSLMH experts can advise on options outside the operating environment described above.)

If you have any questions, comments or concerns about lithium forklift battery packs and want to get the right information for yourself, the knowledgeable experts at BSL Battery – Industrial will be happy to help. Please call us anytime during normal business hours at +86-752-2819-469 or email [email protected] anytime.

If you have any questions, comments or concerns about lithium forklift battery packs and want to get the right information for yourself, the knowledgeable experts at BSL Battery – Industrial will be happy to help. Please call us anytime during normal business hours at +86-752-2819-469 or email [email protected] anytime.

About the Author:

If you have any questions, comments or concerns about lithium forklift battery packs and want to get the right information for yourself, the knowledgeable experts at BSL Battery – Industrial will be happy to help. Please call us anytime during normal business hours at +86-752-2819-469 or email [email protected] anytime.