Inflation-adjusted economic justification tool projects labor savings from packaging automation

Orbital wrapping machine manufacturer TAB Industries, LLC, Reading, Pa., has updated its online Economic Justification Tool to reflect surging inflation in the labor market. Raising the default hourly labor rate from $13.50/hour to $20.50/hour, the Economic Justification Tool reveals that companies upgrading from manual pallet wrapping to an automated or semi-automated TAB Wrapper Tornado orbital wrapper save $25,184.25 in total labor cost savings that recur annually versus a savings of $16,584.75 annually in prior years. Replacing stretch wrapping by hand with the patent-pending orbital wrapper cuts the pallet wrapping process from a two- or three-person job that requires approximately four minutes per pallet load into a one-person job that requires one minute or less. At 30 pallet loads daily, the entry-level TAB Wrapper Tornado Standard model cuts the total labor costs per wrapped pallet load from $3.69 to $0.46.

“The higher the cost of employee compensation, the greater the savings from automating the pallet wrapping function,” says Andy Brizek, vice president of sales and marketing for the family-owned TAB Industries. The inflation-adjusted Economic Justification Tool is available to use for free at https://www.tabwrapper.com/

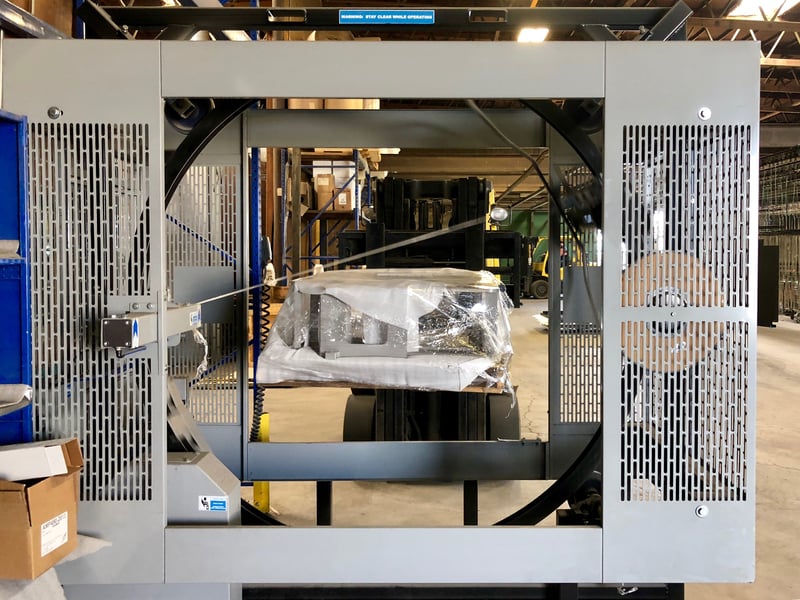

The TAB Wrapper Tornado line of orbital wrapping machines automatically apply stretch wrap 360 degrees around and under the pallet and load to create a sturdy, secure, unitized load in seconds without banding, boxing, or strapping. The stretch wrappers are designed and manufactured at the company’s Reading, Pa. headquarters and delivered ready for operation with a warranty.