Fort Robotics introduces Oversight™, its new safety and security platform for smart machines

Full-Stack platform brings enhanced safety, flexibility, and endpoint security for autonomous and connected machines. Participants at MODEX will get a first look at FORT’s new solution for large equipment

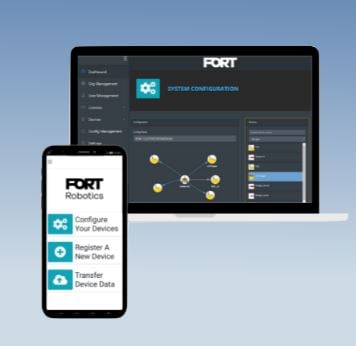

FORT Robotics, a VC-funded company dedicated to safety and security for smart machines, is introducing its next-generation platform, Oversight™. The first-of-its-kind control system enhances worker safety and machine security with built-in encryption, safety-certified communications, and advanced software features with seamless connectivity through web and mobile applications.

FORT developed Oversight after working for several years with over 200 customers, including many of the most advanced robot development teams across numerous Fortune 100 companies, VC-funded startups, and academic and government research labs. Oversight reflects these customers’ need to maintain safe and secure remote control over large machines at all times, even if they’re fully autonomous and connected to the internet. FORT sees Oversight as a critical step in its mission to make robust functional safety and cybersecurity easier to build into smart machines.

“Every machine is becoming connected and autonomous, and we are building Oversight as the protective layer to ensure those machines are safe and secure,” said Samuel Reeves, Founder, and CEO of FORT Robotics. “Construction, agriculture, manufacturing, logistics, and countless niches are being transformed by smart machines, and we want to give the engineering teams developing these solutions the freedom to focus on their applications with the confidence that safety supervision and endpoint security are taken care of.”

Key benefits of FORT Oversight include:

- Remote Control Designed for Autonomy: Advanced collaboration features enable safe control transitions between different machines and users in multiple operation modes– from manual to fully autonomous– with minimal friction.

- Flexible and Future-Proof: WiFi, Bluetooth, ISM, and LTE network options enable global and diverse use cases, for today and tomorrow, plus the ability to use Oversight as the machine’s primary communications gateway.

- User-Configurable Wireless Safety: Expandable safety I/O allows additional safety devices to be integrated and bridged wirelessly.

- Rugged, Ergonomic, Industrialized Hardware: Extreme temperature ranges, ingress protection, and hardened mechanical design on the machine, familiar but rugged form factor in the handset.

- Seamless Configuration and Updates: Smart device integration enables system updates and user access control in the field; web portal provides easy configuration and monitoring of the ecosystem remotely.

- Powerful Security: Hardware-based authentication ensures that only approved operators are allowed to operate machines, approved developers are allowed to modify machines, and approved organizations are allowed to communicate with machines.

FORT’s solution has a number of applications in material handling, uses with AGVs, forklifts and other smart machines as the industry expands autonomous capabilities. “Our solution supports a durable, lightweight and ergonomic remote control that can be used when manual control is necessary for mapping or maintenance or to provide additional safety operations,” says Reeves. “Our solution is designed to support advanced features including Machine Select, to choose which machine to control from a single remote; Mode Select, to transition between supervised control or autonomous operation of a machine, and Access Control to authenticate operation of each user and each machine via our mobile app.”

FORT will be exhibiting at MODEX Booth # 6228.