Mobile robots are crucial to the advancement of Industry 4.0, boosting efficiency, flexibility, and automation within manufacturing landscapes.

Mobile robots are crucial to the advancement of Industry 4.0, boosting efficiency, flexibility, and automation within manufacturing landscapes. Vertical reciprocating conveyors elevate AGVs and AMRs to new levels of efficiency

Vertical reciprocating conveyors (VRCs) act as the pivotal link between two major trends in warehouse operations that are dramatically increasing efficiency and profitability:

- Mobile Robots — The widespread adoption of Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) is transforming the horizontal movement of materials across facilities, revolutionizing logistics and material handling processes.

- Vertical Space Utilization — Driven by the pursuit of logistics efficiency, along with escalating real estate costs and last-mile distribution demands, warehouses and production facilities are optimizing “cube space utilization” by expanding upwards rather than outwards.

Vertical reciprocating conveyors seamlessly integrate the horizontal and vertical material handling processes, facilitating the smooth automated flow of material in three dimensions. These flexible and compact systems can be incorporated into a wide variety of layouts and serve a multitude of different applications.

Combining VRCs with mobile robots and other manual and automated equipment often represents the most efficient, safest, and cost-effective solution for accessing taller racking, pick modules, mezzanines, and multiple floor levels, in virtually any type of warehouse or production environment.

Combining VRCs with mobile robots and other manual and automated equipment often represents the most efficient, safest, and cost-effective solution for accessing taller racking, pick modules, mezzanines, and multiple floor levels, in virtually any type of warehouse or production environment.

Rapid Adoption of Mobile Robots

AGVs and AMRs are revolutionizing logistics across many industry sectors. In factories, these technological advancements automate material handling and assembly line tasks. This not only boosts production rates but also improves workplace safety by taking over hazardous or repetitive tasks from human workers.

Automated Guided Vehicles adhere to predetermined paths, whereas Autonomous Mobile Robots employ sophisticated sensors and artificial intelligence for flexible navigation. AGVs, with their lower initial costs, are sometimes preferred by production and packaging operations in obstacle-free routes where predictable timing of material delivery is paramount. Conversely, AMRs offer unparalleled adaptability in dynamic and chaotic settings, making them ideal for large warehouses and distribution centers.

Mobile robots are crucial to the advancement of Industry 4.0, boosting efficiency, flexibility, and automation within manufacturing landscapes. Their capacity for autonomous navigation and task execution across diverse scenarios renders them indispensable in the drive towards more intelligent and interconnected factory ecosystems.

In warehouses, the impact of these robots is even more visible and transformative. Several factors are driving the swift adoption:

- E-commerce Growth: As E-commerce continues to experience explosive growth, with next-day-delivery expectations and direct-to-consumer marketing models, AGVs and AMRs are key to meeting the demand for quicker order fulfillment and inventory management.

- Complexity of Modern Distribution: The modern warehouses and distribution centers need to rapidly evolve from classic distribution models to an omni-channel model with the agility to pick case packs, fill retail store orders, pick and pack single consumer orders, and process customer returns and product refurbishments.

- Labor Shortages and Rising Costs: With ongoing labor shortages, particularly in logistics and manufacturing, AGVs and AMRs offer a solution by automating repetitive tasks.

- Technological Advancements: Enhanced sensors, AI, and better batteries have made AGVs and AMRs more adaptable and efficient, capable of performing complex tasks autonomously.

- Safety and Efficiency: Compared to forklifts and manual material handling equipment, AGVs and AMRs improve workplace safety and operational efficiency, handling hazardous tasks and operating 24/7 with precision.

Vertical Cube Utilization

Two to three decades ago, distribution centers typically featured clear heights of 24 to 32 feet – the vertical space from the floor to the ceiling. Today, driven by the scarcity and increased costs of land, especially near urban centers, and advances in fire protection and material handling technology, the industry standard for clear heights has shifted to 36 and 40 feet, with demand growing for even taller structures.

The shift towards taller buildings is also fueled by the rapid growth in multi-level facilities, specifically designed to optimize last mile distribution, accommodating the increasing demand for faster and more efficient delivery systems in densely populated areas.

Leveraging the “vertical cube” not only maximizes storage but also streamlines operations, improving material handling, increasing productivity, and ensuring safety without necessitating horizontal expansion. The utilization of upper levels also frees up prime dock-level real estate for crucial shipping, receiving, or re-packaging processes.

Furthermore, the concept of cubic utilization in warehouse and factory design marks a significant shift towards sustainability and energy efficiency. By maximizing cubic space while minimizing the square footage of the building’s exterior envelope, facilities significantly reduce HVAC costs. This approach not only lowers initial investment in land and construction but also yields long-term savings in maintenance, operations, and even property taxes.

Furthermore, the concept of cubic utilization in warehouse and factory design marks a significant shift towards sustainability and energy efficiency. By maximizing cubic space while minimizing the square footage of the building’s exterior envelope, facilities significantly reduce HVAC costs. This approach not only lowers initial investment in land and construction but also yields long-term savings in maintenance, operations, and even property taxes.

VRCs are Ideal for Automated Material Handling

The symbiotic relationship between these two trends — mobile robots and the utilization of vertical space — mediated through Vertical Reciprocating Conveyor technology, exemplifies how the strategic adoption of advanced automation technologies and space utilization concepts can revolutionize warehousing and manufacturing.

A VRC functions like an elevator, with one fundamental difference — VRCs are intended to move material loads, not people. They are regulated as a conveyor (under ASME B20.1) and not people-moving elevators, making them less costly to install and maintain than an elevators.

VRCs have an enclosed platform that prevents loads from falling as they are lifted and lowered. This makes them far safer to operate than forklifts or scissor lifts. VRCs safeguard employees from injuries incurred while transporting items on staircases and deter the misuse of forklifts beyond their safe mast lift height limits.

Flexibility

VRCs are a versatile solution that can be installed next to mezzanines, in existing elevator shafts, or through floors, and they can also be installed outdoors.

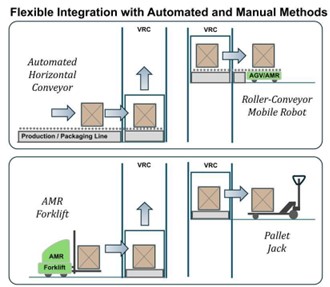

Vertical Reciprocating Conveyors (VRCs) stand out for their exceptional versatility and adaptability, opening a myriad of automated material handling opportunities. They seamlessly integrate with mobile robots and automated conveyor systems, or they can be manually loaded and unloaded.

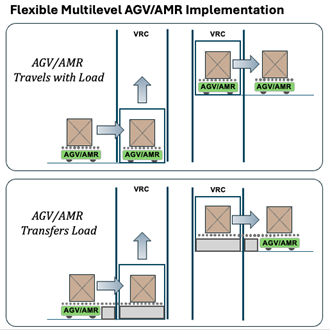

AGVs, AMRs and driverless forklifts can travel with the load on the VCR and continue travel when they arrive at the destination floor. Alternatively, they can efficiently transfer loads onto the VRC at one level, and then another system —whether it’s another AGV, AMR, or a different automated or manual material handling method — can take over at a different level.

Furthermore, VRCs can effortlessly connect with automated horizontal conveyor systems, facilitating the smooth flow of materials to and from production, packaging and shipping operations.

Designed with flexibility at their core, these systems ensure that warehouses and production facilities can stay ahead of the curve, easily adapting to new processes and technologies as they evolve.

Seamless Transition

A seamless transition as the mobile robots travels on and off the carriage is critical. Proper alignment of the floor and the carriage is necessary to prevent damage to the robots and goods and to avoid operational delays during the transfer between the floor and the VRC platform.

PFlow’s optional, patented DeckLock Safety System guarantees a smooth and secure transition of goods during loading and unloading operations, providing years of reliable service even under heavy loads and continuous usage. It also prevents unintended carriage descent due to overload or brake malfunction during loading.

Seamless Integration

The integration of AGV/AMRs and VRCs with Warehouse Management Systems and Fleet Management Software represents a significant leap forward in material handling efficiency, ensuring a fluid and cohesive operation within the material handling ecosystem. As a result, these robots can autonomously transport or collect goods across different facility levels, minimizing the need for human intervention and significantly boosting throughput and operational effectiveness.

Critical to this integration are the features and capabilities that facilitate real-time communication and interoperability among AGVs, AMRs, and VRCs. This integration ensures that robots can autonomously and precisely position themselves to either load or unload goods onto the VRCs. The employment of advanced sensors, visual systems, and Internet of Things (IoT) technologies enables these machines to share their locations, statuses, and the movement of the carriages within the VRCs, thereby streamlining the material handling process.

Multiple Configuration Options

VRCs’ flexibility and customizability mean they can integrate seamlessly with complex automated material handling systems and fit into tight spaces.

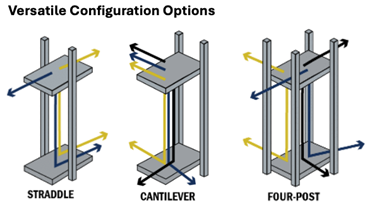

Three basic configurations are available.

Straddle

In a straddle configuration, the VRC’s carriage is placed between the two guide columns, distributing the weight of the load vertically along the length of both columns. This type of configuration allows for greater lifting capacity and larger carriage platform sizes than a cantilever configuration.

The straddle layout allows for C loading (load and unload from the front) and Z loading (load and unload on opposite sides) patterns and is a great option in applications that do not have space constraints and do not require unlimited load height.

The straddle layout allows for C loading (load and unload from the front) and Z loading (load and unload on opposite sides) patterns and is a great option in applications that do not have space constraints and do not require unlimited load height.

Cantilever

In a cantilever configuration, the VRC’s carriage is supported by two guide columns on one side of the carriage, allowing for more loading and unloading flexibility to maneuver loads, especially in space constrained areas.

This configuration allows easy access from three sides of the VRC and supports three load patterns; a C load pattern (load and unload from the front); a Z load pattern (load and unload from opposite sides); and a 90-degree load pattern (load from the front and unload from the side).

4-Post

The 4-post VRC configuration positions the platform within four guide columns to enable maximum lifting capacity and large platform sizes.

This configuration is well-suited for applications that require lifting and lowering large, bulky and/or oversized or extremely heavy loads. The configuration of the 4-post system also enables workers to load or unload from any size of the carriage for maximum flexibility.

Comparing Mechanical versus Hydraulic VRCs for Automation

VRCs are engineered with robust core lifting technology, utilizing either hydraulic or mechanical systems. Hydraulic VRCs are effective for simple two-level lifting tasks that do not necessitate continuous operation.

For most automated processes, mechanical VRCs are preferable. They are engineered for handling heavy loads, achieving high speeds, and enduring continuous cycle operations. Suitable for applications that extend beyond 22 feet in height or require lifting capacities exceeding 6,000 pounds, mechanical VRCs can transport loads up to 10,000 pounds and reach heights surpassing 100 feet.

VRCs can lift material loads weighing as little as 10 lbs. to loads weighing over 100,000 lbs., to two or more floor levels. Unlike other material lifting equipment, VRCs have an enclosed platform that prevents loads from falling as they are lifted and lowered. This makes them far safer to operate than forklifts or scissor lifts.

Revolutionizing Material Handling Efficiency

Vertical Reciprocating Conveyors are fundamentally transforming warehouses and production facilities by extending the potential of mobile robots and facilitating unprecedented efficiency in vertical cube utilization. By enabling the seamless vertical movement of materials, VRCs maximize space in facilities and accelerate the automation process, resulting in faster, safer, and more cost-effective material handling solutions. Consequently, the adoption of VRCs is not just an operational improvement — it’s a strategic upgrade that positions warehouses and production facilities at the forefront of innovation and efficiency.

About the author

Chuck Cobb, Vice President Sales, Marketing, & Customer Support and Dan Hext, National Sales Director, PFlow Industries