How to select a proper dock lift for your operation

Hydraulic Dock Lifts have two advantages over other means of unloading trucks: Level unloading from the bed of a truck is safer than any other alternative, and Loading Dock Lifts are the only type of equipment that can reach from ground level to all sizes of trucks ranging from low step vans to large refrigerated reefers. There is no vehicle size that dock lifts cannot service.

Once you realize the benefits of level loading with dock lifts, the next question is which type of loading dock lift system best fits your application and what options should you consider.

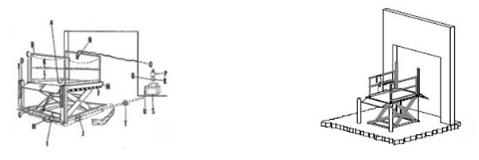

Top of Ground Style or Pit Mounted Recessed Lift

The first consideration is which of these hydraulic truck lift alternatives is best for your application.

- Top of Ground Advantages

These units can be mounted on any flat concrete slab (units will sink into blacktop during the summer) and require no pit work. This not only avoids the cost of a pit, but also drainage issues and potential interference with underground utilities. If you decide to move the unit later (we have reports of units providing as many as 35 years of continuous service) it is an easy matter to unbolt the unit and move it with no pit left to fill in. Capacities range from 4,000 lbs. up to 15,000 lbs. and platform sizes range from 6’ X 6’ up to 8’ X 12’. The cost of top-of-ground units are always higher than the cost of recessed units, however, when the cost of pit construction is added to the equipment prices, top-of-ground units can be competitive.

- Recessed or Pit Mounted Advantages

The equipment costs for these units are always less expensive than top-of-ground units. The biggest advantage is the fact that these hydraulic dock lifts are mounted flush with surrounding surfaces so they do not become an obstacle to drive over traffic. This is especially important if the unit is being mounted in a doorway. Top-of-ground units have ramps that transition loads from the platform to ground level which is fine for offloading operations but can be tiring if heavy loads must be pushed up the ramps for loading trucks. Standard capacities of recessed units range up to 20,000 lbs. Recessed units offer level loading both at ground level and at truck height. If recessed units are mounted within the face of docks they can provide easy dock-to-ground access, although top-of-ground units can do the same if the approach ramps are shortened and the units are mounted immediately adjacent to the dock.

Platform Size

The platform size is primarily determined by the type of transport equipment that will be used to load or unload trucks. The minimum suggested platform width is 6’. Guardrails use 4” to 8” of usable platform width on some models and there should be at least 4” of clearance on each side of the widest load such as a 48” wide pallet for ease of maneuvering. In some cases, the loads may be wider and some users like to unload two pallets side by side so 7’ and 8’ wide platforms are common options.

If the loads are four-wheeled carts or baskets, or the loading equipment is limited to two wheeled hand carts, then a 6’ platform length is sufficient. For manual pallet jacks, 8’ platform lengths are considered minimum. Powered pallet jacks work best with 10’ lengths to comfortably fit the load, powered pallet jacks and operator all in line. Straddle stackers also fit well on 10’ platforms. Fork trucks are much longer so they generally require platforms in the 10’ to 12’ range.

The size range mentioned above covers 99% of all applications and is now available as standards in both top-of-ground and recessed styles of loading lifts. Unusual loads may require custom-designed units with platform widths of 10’ or 12’ and platform lengths of up to 65’. If you have special requirements, a full-service supplier can help you design a perfect fit.

Capacities

- Lifting Capacity

Once a platform size has been determined, it is a simple matter of adding up the maximum weight of the goods being transferred, the weight of the transport equipment and the weight of an operator to arrive at a lifting capacity.

- Axle Rating Capacity

The axle loads on manually propelled carts and pallet jacks are too light to be of concern. Manual pallet jacks divide payload weight evenly between two axles, but powered pallet jacks and straddle stackers often concentrate 60% of the combined payload and equipment weight on their rear axle and they can move heavier loads than manual equipment. Fork trucks usually concentrate 80% of the maximum payload plus fork truck weight on the front axle, but some unusual trucks may run as high as 90% concentrations. Most manufacturers have appropriate end load axle ratings for corresponding maximum lifting capacities, but there is always the danger that you have unusual equipment and/or if your application requires traveling over the side of the lift in anything other than the fully lowered position, there is a possibility that the side axle rating is marginal. It is wise to compare the axle loads produced by your equipment vs. the rating of the dock lifts to be safe.

- Roll Over Capacity

This only applies to recessed units and refers to the maximum axle load allowable for vehicles driving over a fully lowered lift. Most recessed dock lifts are rated for 10,000# axle load slow speed drive over. This is usually more than adequate because of state mandated limits on truck axle loads. However, large specialty vehicles and high capacity fork trucks with small hard wheels can exceed these limits. In those cases, warn the lift manufacturer and they can modify the lifts to accommodate larger loads with thicker deck plates and other forms of reinforcement.

- Power units and controls

The up-down controls must be controlled by the operator riding on the lift. Any other scenario is a sure recipe for an accident. Standard controls for most companies are NEMA 4 pushbuttons. These are usually mounted on straight cords or coil cords. For security options, the cords can be made longer so that they can be connected to boxes inside secure buildings or mounted with twist lock plugs so that they can be stored in secure areas until they are needed. In other instances, the handheld controls are replaced with key lock pushbuttons that are mounted on the platforms. Some retail chains specify that all the keys in their system are the same. Limit switches may be added to cause the lift to stop at fixed dock heights. Power units on top of ground units are usually mounted on the lifts and covered with weather protection. Recessed lifts typically have remote power units that are mounted inside buildings, but weather covers can be ordered for outdoor mounting. Oil immersion heaters are important options for power units that will be exposed to cold winter outdoor temperatures.

- Bridges

The size is dictated by the gap from the lift to the back of the truck bed which is determined by the location of the bumpers or bollards that are used to stop the truck’s rearward progress toward the lift. There should be a 4” to 6” extension onto the truck bed. When lifts are located inside buildings with a wall between the lift and the truck, the bridge can rest against a wear strip on the wall and will then automatically reach into the truck as the lift is elevated and retract as the lift is lowered. These bridges are typically very long, but because no one needs to handle them, the extra weight is not a concern. Bridge weight is dependent on both length and capacity. Generally, manually operated bridge weight is a concern when bridges reach 24” or longer. Options to mitigate bridge weight include splitting the bridges into two sections, aluminum bridges, or hydraulically operated bridges with push button controls.

There are too many options to list them all, but they include special paint finishes, special platform surfaces, wheel chocks, hydraulic fluids, gates & much more.

By Henry J. Renken, Advance Lifts, Inc.