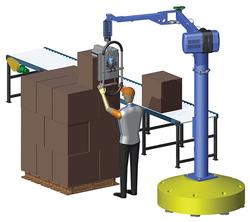

WEPCO, Inc. SmartLifter- offers a new way to grip, lift and stack cartons

WEPCO, Inc. announces the SmartLifter™ automated vacuum carton lifter. It grips, balances, and stacks cartons with fingertip pressure. SmartLifter (patent pending) was designed in response to a request from a major plastic container manufacturer. They were seeking a solution to a problem common to many manufacturing and warehouse operations: how to reduce the physical strain of repetitive lifting and stretching while manually building tall pallet loads. WEPCO designed a prototype and perfected it with the client’s input. “This is a great example of how, when the customer is included in the development process, everyone wins,” says Chris Paulsen, WEPCO’s CEO. Perfect for building pallets at the end of a line, SmartLifter solves endless productivity problems. It reduces worker strain, increases productivity, stacks pallets more snugly, allows for easy reconfiguration of lines, handles a wide range of carton sizes, and has a clean, virtually maintenance-free design. It can handle any pallet configuration, and even short operators can easily stack a 9’ pallet. Since cartons are gripped on only one side, product loss due to top seal failure is eliminated.

Here’s how it works: SmartLifter grips cartons on one side. The vacuum engages automatically when the SmartLifter is placed on the carton. As the carton is lifted, exclusive SmartBalance technology senses and adjusts to steady the load, eliminating tipping. The force-sensing handle provides fingertip control and is ergonomically designed to give workers increased freedom of position, visibility and control. The vacuum releases the carton automatically when the operator places the carton. SmartLifter is powered by Gorbel® G-Force® and made of anodized aluminum. It allows for 360° rotation and has boom reach up to 12 ft. radius. When mast-mounted on WEPCO’s BigFoot™ portable base, it is easily moved with a pallet jack or fork truck. The underhung model, mounted on a monorail, can serve multiple production lines. A patent is pending.