UK’s first HALTER CNC robot boosts flexibility at FB Chain

FB Chain took delivery of the UK’s first robotic loading arm by HALTER CNC Automation this summer to support one of its anchor bolt milling machines. This investment has significantly improved FB Chain’s ability to provide a quick turnaround for customers even at short notice.

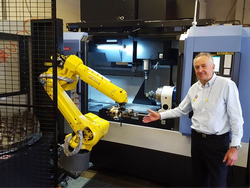

FB Chain’s manufacturing manager Nigel Eames proudly introduces the newest addition to the company’s production facility, the HALTER LoadAssistant®. Having seen the HALTER LoadAssistant® in action at several reference plants in Germany, FB Chain became the first company to employ one in the UK in June. Based in Letchworth, Hertfordshire, FB Chain has been manufacturing and supplying leaf chain, anchor bolts, pins and pulleys for forklift trucks and other materials handling equipment for 30 years and is the UK Fork Lift Truck Association’s 2015 Supplier of the Year.

“Even in mainland Europe this technology is fairly new – there are less than 20 of them working in manufacturing facilities across the continent – so this was a calculated risk for us. And it has paid off,” Eames says.

Since its installation the robotic loading arm, including software from leading robotics company Fanuc, has increased output from its assigned CNC milling machine by at least 150 leaf chain anchor bolts per day with minimal supervision.

“Automation normally works best for high volumes and repetitive tasks. We make small to medium volumes of similar parts so automating our processes is hard. The loading module with twin decks on the HALTER means that it can switch between parts quickly and work on batches as low as 40.

“Like many businesses, demand at FB Chain fluctuates and having too many or too few staff on shift affects the level of service we are able to offer our customers. The new robot has enabled us to ramp up production quickly without having to find extra staff and its safety mechanisms means that it can even be left to run overnight if required,” he says.

Reducing lead times

FB Chain aims to reduce its lead times to less than four weeks and with the help of the HALTER LoadAssistant® this goal is becoming closer and closer. The company has also recently upgraded its bar-fed turning centres with quadruple tooling, which can likewise be run safely overnight, to further shorten customers’ lead times. Next year the company plans to install a fully automated manufacturing cell for its leaf chain anchor blocks.

“At FB Chain we are constantly reviewing and optimising our manufacturing processes and equipment for the benefit of our customers. Our promise is to provide consistently high quality materials handling chain and associated parts at our customers’ convenience – and continuous improvements are required to guarantee this,” Eames concludes.