Telematic forklift monitoring may pair well with new High-Tech Glasses

Forklift downtime can easily derail your facility’s best efforts to deliver product and meet customer demands. Unexpected downtime is the nemesis of productivity.

When forklifts and equipment fail, it can be challenging to get things up and running quickly unless your enterprise has dedicated, on-site service technicians. But relatively new technology, in the form of wearable glasses, may help address immediate repair issues for businesses that lack on-site technicians.

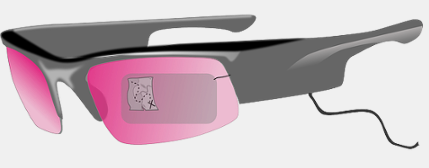

The solution is based on Google glasses, but with a focus on maintenance and repair needs in the warehousing industry. Essentially, anyone can slip on these glasses and be connected instantly with a remote technician.

How forklift monitoring and high-tech glasses will work together

If your warehouse already uses telematic software to monitor safety and maintenance checklists, real-time movement of forklifts, and diagnostics, adding some expert repair guidance via hi-tech glasses could be the next step to reducing downtime.

The speed at which a warehouse can facilitate repairs is an ongoing challenge for many. Regulations require employers to put safety procedures in place to lockout a vehicle in need of repair. But failing to use a lockout is one of OSHA’s most cited safety violations. One of the reasons for this is the amount of time it takes to get a technician on-site to complete repairs.

Faster solutions

These glasses will allow even an inexperienced on-site technician to perform required maintenance immediately. They work through a Wi-Fi or Bluetooth connection and allow an experienced remote technician to see everything the on-site person sees. The worker wearing the glasses is instructed through each step of the repair using augmented reality and voice directions.

Your telematic monitoring software will further support this technology, providing background information to aid in the diagnostics. It delivers insight on maintenance, previous mechanical issues, and impacts the forklift may have been involved in or affected by. It can even provide information about how driver behavior, such as excessive speed, may be a contributing factor to the repair needed.

The high-tech glasses typically combine a video camera, augmented reality, a microphone, and a barcode scanner. The combination of these technologies in a lightweight, mobile, wearable, hands-free device is expected to be in the hands of most warehouse enterprises within the next few years.

This advanced technology is being developed by several companies and is evolving rapidly. Combined with a telematic software platform that delivers real-time forklift monitoring and documents all maintenance and repair issues, downtime can be significantly reduced without relying on onsite technicians.

Topics: labor costs, lift truck fleet management, SX/VX, smart systems, forklift costs, fleet monitoring, telematic diagnostics, Lean warehousing, value driven strategies