BEUMER’s BG software suite provides optimal control of material flows

The BEUMER Group introduces the BG software suite which allows customers to control their material flows from start to finish. The suite can be adapted to each company’s special needs. Third-party products can be integrated without difficulty.

BG, which stands for BEUMER Group, is the name for the company’s software suite for high-level computer systems. The suite’s modular structure allows users to adapt it to their machinery and equipment and add modules at any time in order to optimize their material flows. The Beckum-based intralogistics specialist also provides the BG Fusion interface, which displays process data, reports and machinery statistics for all parts of the program. Users can call up data on their monitor without having to switch between applications. BG Fusion is fully scalable, meaning it can run on desktop PCs as well as mobile devices like tablets.

Customized for each user

The left area of the interface displays important information in a compact form for all users. The main area is reserved for data relevant to the particular application. Three different desktops are available. Users can store their individual settings so that they can go right to work with the same data when they log in again. The user interface can also be switched between different languages. The web-based interface runs on all current Windows operating systems. Users can export all data displayed on the screen to PDF or CSV files. A screenshot function is also included.

Smooth communication

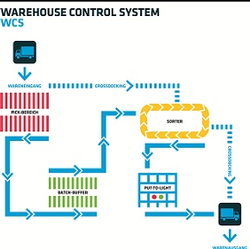

The BEUMER Group Warehouse Control System (BG WCS) module allows the BG software suite to link up with the customer’s warehouse management system or ERP system via a network connection. Thus communication is possible between different control levels.

As a full-line supplier, the BEUMER Group can draw on many years of experience in control and automation technology. It is able to plan and implement complex projects in intralogistics, including intelligent linking of machinery and systems and their integration into existing process control or merchandise information systems. Customers get everything they need from a single source, interfaces are avoided, and possible sources of error are eliminated.