Christmas came early for Handling Specialty

20901 Torrence Chapel Rd

Cornelius, NC 28031

Phone: 888-247-3150

http://www.handlinginnovations.com

The new paint booth and blast booth gracing Handling Specialty’s plant 2 in Hamilton, Ontario expand on HSML’s presence as one of the world’s top custom material handling design/build companies.

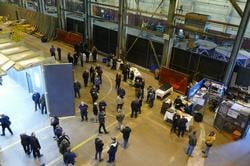

To celebrate the new additions, the company hosted a ribbon-cutting, busing employees in from plant 1 in Grimsby, to experience the new equipment and enjoy catered food and drink on-site. The celebration also included an inspired educational speech from President, Tom Beach who spoke to the benefits of housing their own paint and blast booths, and the additional work they will bring in as a result.

The Industrial Pressurized Semi-Down Draft Spray Paint Booth with external dimensions of 18’W x 49’L x 11’H allows for product parts to undergo the paint process on-site up to dimensions of 16’W x 45’L x 11’H. The paint booth includes a galvanized Finish, exhaust system with LED lights, one air replacement unit, Spray gun Interlock kits with air flow manometer, Integrated electrical control panels with time relay and digital temperature controller, Variable electronic speed control system for spray booth exhaust fan, Reinforced exhaust filter chamber with a 30’ exhaust stack and a Fire protection dry chemical sprinkler system. The booth was provided by United Paint Booths with an Air/Air assist spray paint system by Graco.

The new Blast Booth includes an IBT 40’ Long Air Blast Room, IBT 30’ Long Crane Slot Assembly, Powered Door and Structural System, an IBT “Single Auger” Reclaim System, Man Load Bar Grating, HD 1/4” thick Elevator Assembly, an IBT Measured Media System for Improved Economy, PLC Controls, an Axxiom, “Dual Outlet” Blast Pot, 11,200 CFM IBT Cartridge Dust Collector, Secondary/ After Filter Assembly (To return exhaust air back into the building), Exhaust Fan Silencer (To reduce noise from dust collector), Rotary Valve Assembly (To automatically empty dust from dust collector hopper), and a Pressure Relief Panel on Dust Collector.

The blast booth was built on-site by IBT Abrasive Air Blast System.