BSLBATT receives $1.65M replacement order for Yale, Toyota Jungheinrich, Nichiyu and Still forklift batteries

BSLBATT battery is a fast-paced, high-growth (200% YoY ) hi-tech company that is leading the adoption of lithium-ion technology solutions. We design, manufacture, and sell advanced lithium-ion battery packs that are disrupting the 100+-year-old market for lead-acid batteries. Today announced the receipt of a battery purchase order through its BSLBATT sales channel valued at about US$1.65 million. The batteries will be used by a leading forklift Dealer company to power end customers in Material Handling, Paper and Packaging, Food and Beverage, Refrigerated Storage, Manufacturing Industry, Fresh Produce, Wine Industry, Distribution, and 3PL industries in a new distribution center in South East Asia.

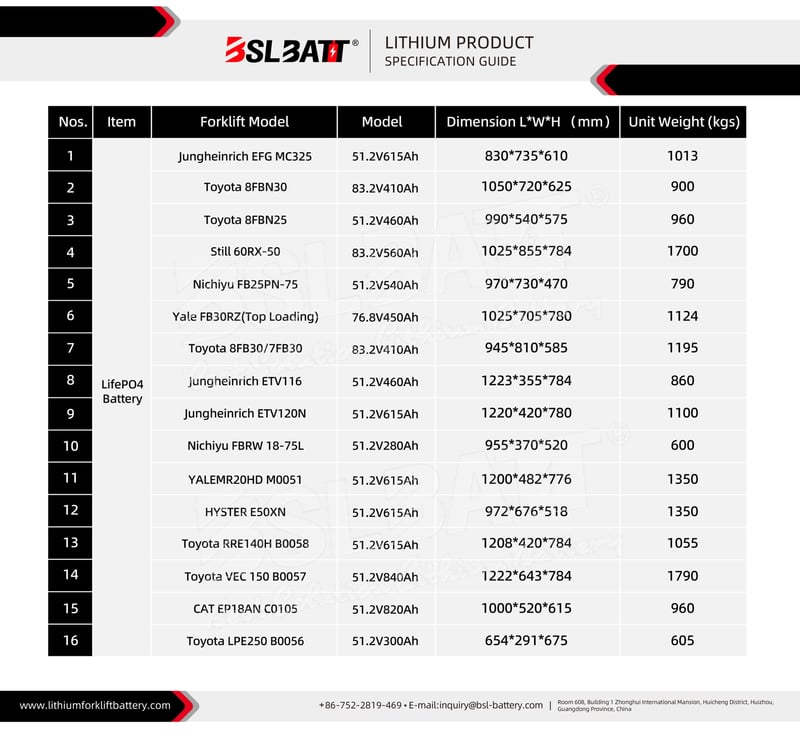

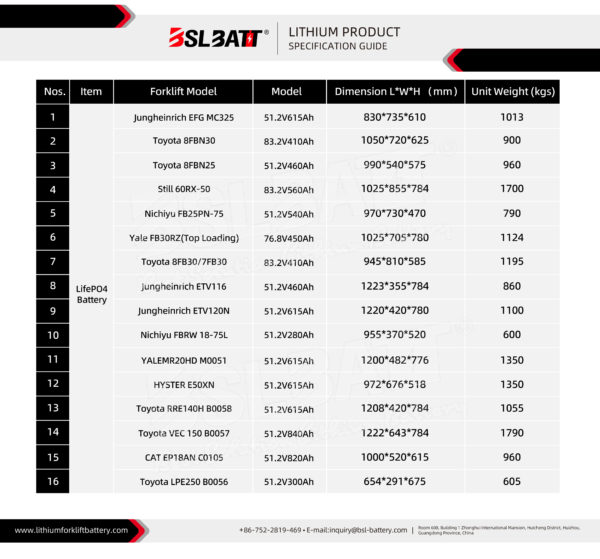

The purchase order follows the company’s announcement on November 24, 2022, to confirm receipt of the customer’s 30% deposit to start production. A detailed description of the specific purchase order for the battery model and delivery location is shown in the figure below. The company expects to deliver batteries in its fiscal fourth quarter ending December 31, 2022.

The purchase order follows the company’s announcement on November 24, 2022, to confirm receipt of the customer’s 30% deposit to start production. A detailed description of the specific purchase order for the battery model and delivery location is shown in the figure below. The company expects to deliver batteries in its fiscal fourth quarter ending December 31, 2022.

What made the customer decide to replace the lead-acid battery on the original forklift?

With lead-acid batteries, Jenny Zeng says, trucks typically cycle through 8 hours of use, 8 hours of charging, and 8 hours of cooling per day to accommodate acid-level maintenance and other maintenance requirements. “It’s a very delicate process if done right; people who do it right can make their lead-acid batteries last a long time. Unfortunately, the reverse is also true. If people are careless, they will experience things like running Issues like short times, battery sulfation, and even acid leaking onto the floor. With lead-acid batteries, maintenance can become an issue, and the battery life is not five or six years, but three or four years.”

In addition, the charging room of the warehouse needs air conditioning and ventilation fans to reduce the toxic gas released when the lead-acid battery is charged. This is not a problem with lithium-ion batteries. “Concerns about corrosive acids are gone. Handling batteries and switching at the start and end of each shift is gone,” Jenny Zeng said. “You can put the charging room space to its maximum and best use, not just overhead.”

Other benefits of lithium-ion batteries include:

TOLL

– More flexible charging times: “opportunistic charging” (i.e. charging anywhere, even for brief downtimes such as lunch breaks)

– No off-season maintenance: the lithium battery can be turned off and idle for 3-9 months at a time, then turned on and put into use with negligible power loss

– Fast charging (2 hours or less), no “memory” effect

Performance

– Fast lifting and travel speeds at all discharge levels (no voltage drop)

– Single battery operation with multi-shift charging

– Service life > 3,500 cycles

Cut costs

– Longer service life: The expected service life of lithium-ion batteries is at least twice that of lead-acid batteries. With a typical new lithium battery forklift lease, the Li-on will likely last for two three-year leases. Afterward, it is still possible to transfer it to second-hand equipment or repurpose it (e.g. for energy storage)

– Zero routine maintenance

– Reduced wear and tear on forklift parts

“This is not only an exciting project but also demonstrates the company’s ability to quickly deliver large-scale projects. Considering the rapid rise in demand for rental lithium battery forklifts by end users in the Southeast Asian market, we expect that by the end of this year, this user will become BSLBATT Southeast Asia The largest forklift rental battery operator in the regional lithium battery replacement lead-acid market,” said Mr. Haley, Chief Operating Officer of BSLBATT.