BSL Battery receives certification for LiFePo4 forklift batteries

1/6/7F-1 Building1 Zhongkai Innovative Base

Huifeng 6th Road ZhongKai Hi-tech Zone

HuiZhou City, Guangdong, INTL

http://www.lithiumforkliftbattery.com

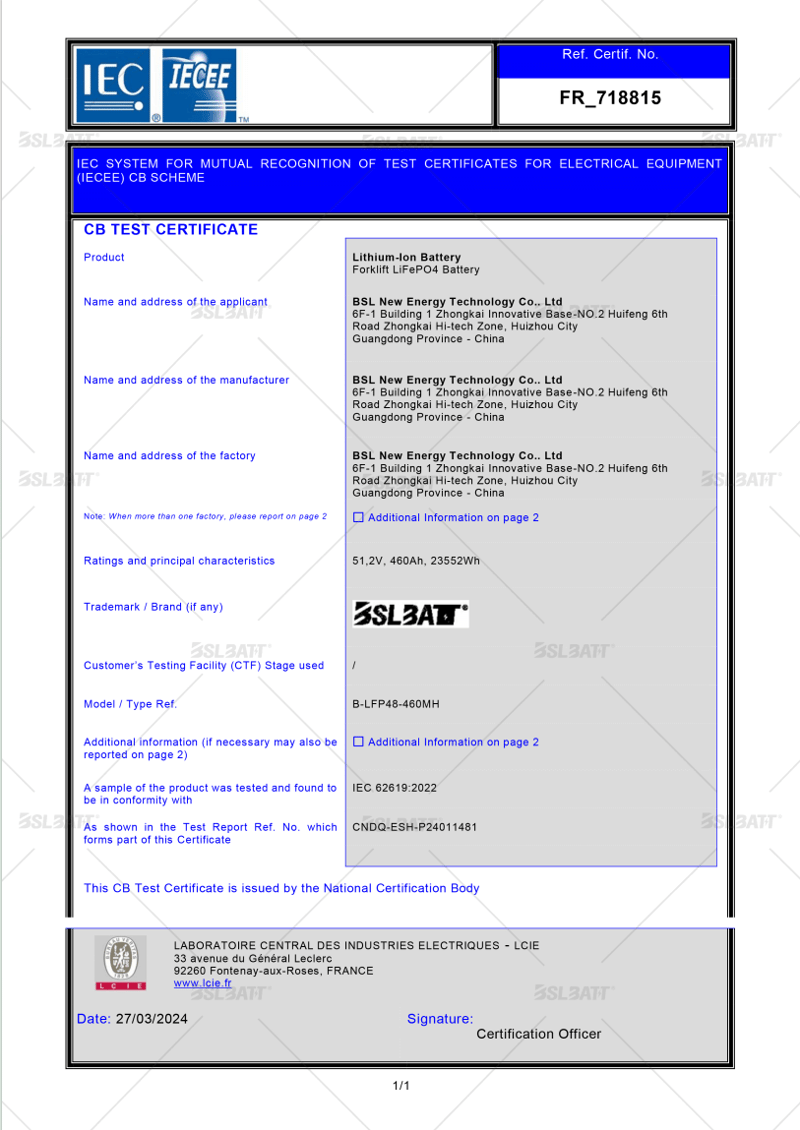

Innovation, quality, and safety have always been fundamental factors in the design and manufacture of BSL Battery – Industrial’s Lithium Iron Phosphate batteries. With the breakthrough of UL2580 and IEC 62619 certifications, BSL Battery-Industrial’s commitment to safety and design excellence remains unmatched. This milestone solidifies BSL Battery-Industrial’s position as a leader in the power industry.

BSL Battery – Industrial, a recognized manufacturer of lithium-ion forklift batteries, has announced that the B-LFP24-205MH, B-LFP36-820MH, B-LFP48-460MH, B-LFP48-615MH, and B-LFP80-460MH lithium-ion (Li-ion) battery portfolios have received UL2580 and IEC 62619 certifications. UL2580 is the standard provided by UL, the global safety science organization, for battery products at the cell, module, and battery pack level to ensure safe use in a variety of power or transportation-related applications. IEC 62619 specifies requirements and tests for the safe operation of rechargeable batteries and battery packs in industrial applications. This prestigious certification will now apply to BSL Battery – Industrial Forklift Lithium Batteries.

BSL Battery – Industrial, a recognized manufacturer of lithium-ion forklift batteries, has announced that the B-LFP24-205MH, B-LFP36-820MH, B-LFP48-460MH, B-LFP48-615MH, and B-LFP80-460MH lithium-ion (Li-ion) battery portfolios have received UL2580 and IEC 62619 certifications. UL2580 is the standard provided by UL, the global safety science organization, for battery products at the cell, module, and battery pack level to ensure safe use in a variety of power or transportation-related applications. IEC 62619 specifies requirements and tests for the safe operation of rechargeable batteries and battery packs in industrial applications. This prestigious certification will now apply to BSL Battery – Industrial Forklift Lithium Batteries.

The UL2580 and IEC 62619 safety testing of forklift lithium-ion batteries has several benefits:

- By complying with the requirements and tests specified in the standard to ensure product safety, manufacturers can ensure that consumers use their batteries safely.

- It is well known that lithium-ion batteries can catch fire or explode if not properly designed, manufactured, or used. UL2580 and IEC 62619 mechanical testing and electrical testing help identify potential safety hazards and reduce the risk of accidents.

- Many countries have regulations that require products containing lithium-ion batteries to meet certain safety standards. Testing UL2580 and IEC 62619 can help manufacturers meet these requirements in the global marketplace.

- Consumers are becoming more aware of the potential safety hazards associated with lithium-ion batteries. By testing UL2580 and IEC 62619 and complying with the standards, manufacturers can gain consumer trust and differentiate their products from competitors.

- The mechanical testing, electrical testing, environmental testing, and test procedures for tolerance to battery failure specified in UL2580 and IEC 62619 can help identify potential quality issues with lithium-ion batteries, thereby improving product quality, design, manufacturing, and performance.