MHS automates parcel processing

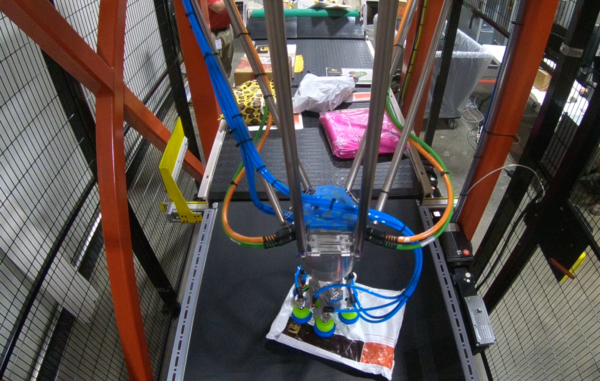

Material Handling Systems, Inc. (MHS) combines advanced computer vision, controls, gripping technology and a five-axis delta robot to automate the task of singulating items in preparation for sorter induction. Ideal for parcel processing operations handling bulk quantities of smaller-size packages, the robot uses proprietary vision software and algorithms to pick individual items from bulk flow then properly orient them and place them in a single-file stream for downstream processes.

The solution uses a vacuum-based end effector with a variety of suction cups to reliably handle packaging types commonly found in e-commerce and parcel processing environments, from rigid corrugate cases to malleable polybags. For distribution centers struggling to find and retain labor for repetitive material handling tasks, the robotic singulator from MHS enables them to reassign employees to higher-value tasks while achieving performance that matches or exceeds manual processes.

Compared to conveyor-based singulation machines, the robotic solution has a much smaller footprint and reduced labor requirements. In addition to preparing items for downstream sortation processes, the robotic singulation technology is well suited for a variety of manufacturing and distribution applications.

Visit MHS at ProMat booth #N6539